Product details

Spot an error? Let us know!

Headline

Model 3175 - Water Treatment Controller

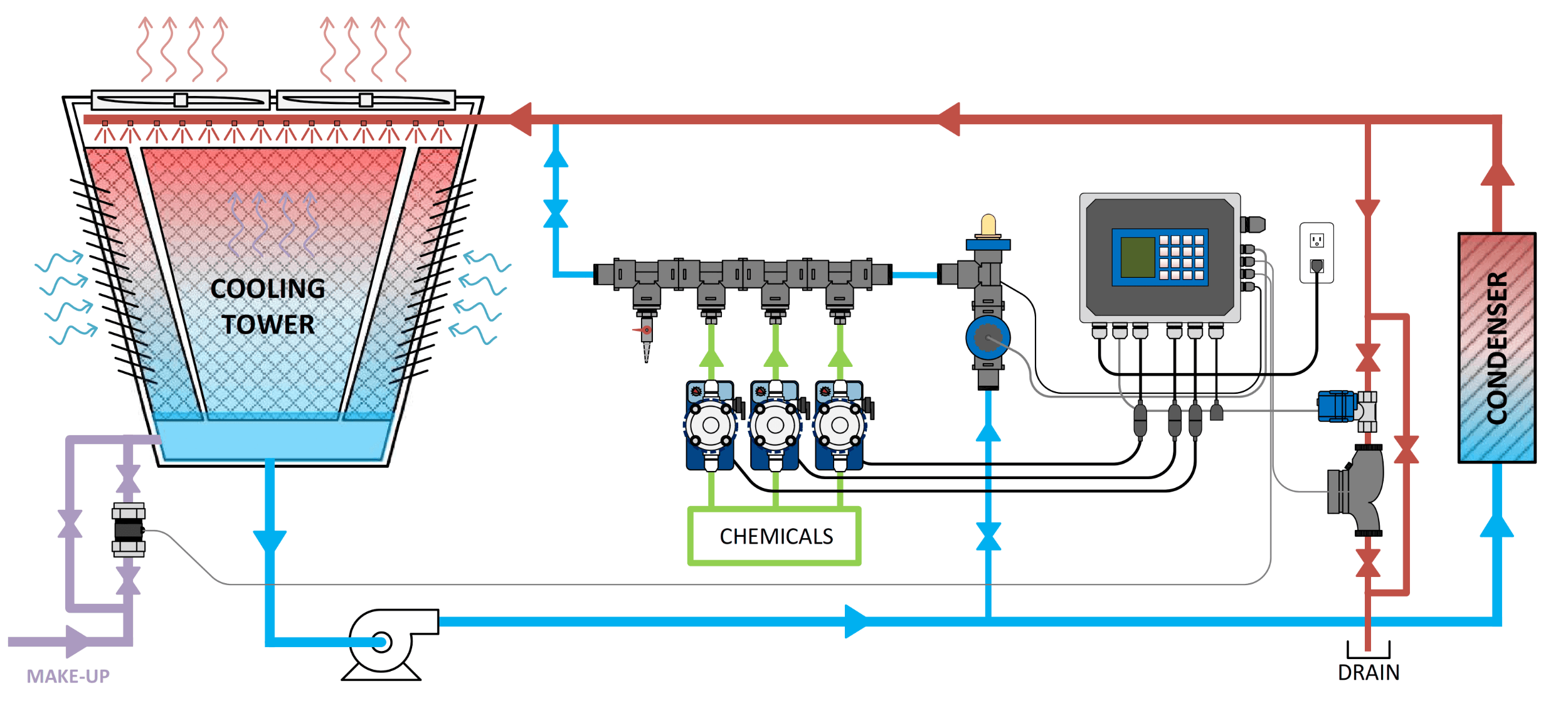

The Model 3175 is a microprocessor based, touchscreen, menu driven, Water Treatment Controller designed for use in cooling towers, chill loops, boilers and condensate systems. The Model 3175 provides for conductivity tracking and control, flow monitoring and chemical injection. The Model 3175 includes a 4-20Ma input that can be used for remote conductivity, or pH, or traced chemistry control, or makeup conductivity for cycles of concentration control, or as one of several other different inputs. The Model 3175 can be operated with or without the use of the conductivity input.

Cooling Towers

Boilers

Features & Benefits

Features:

- 7 inch capacitive touchscreen.

- Data Logging via on-board micro SD card.

- Email notification of alarm conditions.

- Controller can be used for Cooling towers, Chill loops, Boilers, and Condensate systems

- Removable power cord and receptacles for conduit installations. Enclosure is rated NEMA 4X

- Five user configurable relays for conductivity control and chemical addition. These relays can be configured in multiple ways including scheduled feed for biocide addition.

- Two (2) water meter inputs, two drum switch inputs, conductivity input, flow switch input, 4-20 mA output, and a 4-20 mA input are all standard features.

- Designed with a single circuit board for high reliability and lower cost.

- Large open shallow enclosure for easy wiring.

- Ball valve delay feature allows accurate control of motorized ball valves.

- Easy to program, the Model 3175 Controller uses an intuitive menu and programs identical to the Lakewood 2000 Series controllers.

- Controller can be removed from a cooling tower and be placed in another type of application when used with the appropriate conductivity sensor and plumbing assembly.

Benefits:

- Modern Connectivity & Data Logging

- Responsive Touchscreen

- Simple to Configure

- Affordable

- Updated Processor

- Five (5) Relays

- No add-on options. 4-20mA output, 4-20mA input, and biocide features are standard.

Additional Notes

Specifications:

- Conductivity range: 50-10,000 μS

- Conductivity sensor: 2 electrode

- Conductivity Resolution: ± 10 μS (conductivity <5000 μS) / ±100 μS(conductivity > 5000 μS)

- Temperature comp.: 500NTC, NONE

- Accuracy & repeatability: ± 1.0%

- Deadband/Setpoint: Programmable

- Auto/Manual outputs: Menu selectable

- Interface: 7 inch capacitive touchscreen

- Drum Switch Inputs: 2 digital contact inputs

- Water meter inputs (2): Contact head, paddle wheel, or turbine

- Timers: Max. blowdown time exceeded and relay run time exceeded

- Output Signal: One 4 – 20 mA, isolated or non-isolated optionally powered output for conductivity

- Input Signal: One 4-20 mA, non- isolated internally powered input for conductivity

- Output relays: 5, 4 selectable use, 1 blowdown

- Relay ratings: 3A each, 10A total

- Power: 120/240 VAC 50/60 Hz

- Ambient: 32° - 120°F (0 - 49°C)

Wiring:

Cooling Tower

Boiler

Plumbing:

| Sensors | Cooling Tower | Boiler |

|---|---|---|

| Max Pressure | 140 psi (9.65 bar) @ 100 °F | 600 psi (41.3 bar) |

| Max Temp | 140°F (60°C) | 486°F (252°C) |

| Min flow | 1 gpm (3.785 Lpm) | - |

Dimensional drawings

Call or text: +1 (484) 544-0506

The Supplyline team is here to help!